www.doulos1914.blogspot.my

www.doulos1914.blogspot.my

A rivet is a permanent mechanical fastener. Before being installed a rivet consists of a smooth cylindrical shaft with a head on one end. The end opposite the head is called the buck-tail. On installation the rivet is placed in a punched or drilled hole, and the tail is upset, or bucked (i.e., deformed), so that it expands to about 1.5 times the original shaft diameter, holding the rivet in place.

Because there is effectively a head on each end of an installed rivet, it can support tension loads (loads parallel to the axis of the shaft); however, it is much more capable of supporting shear loads (loads perpendicular to the axis of the shaft). Bolts and screws are better suited for tension applications. It is said that the older-riveted ships were more 'flexible' in rough seas than the modern welded hulls.

These are original riveting done when Medina was laid to keel in 1914.

You are looking at it in present times, how exciting! - provided by www.ssmaritime.net

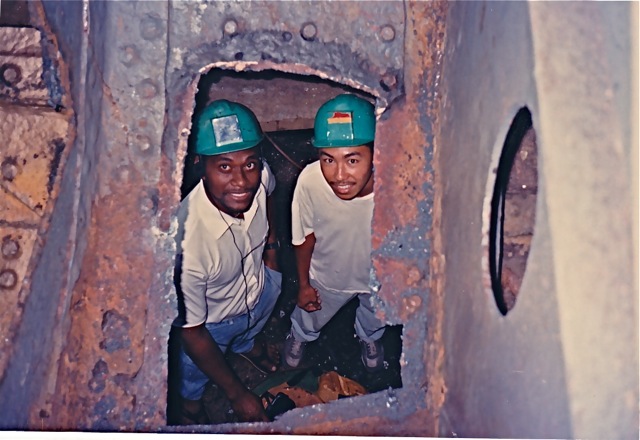

"Me" and Joe Saemala (Bosun). There was a little 'hole' we found this bilge section. We had it cut out and welded on with a new plate. You can see the original construction using rivets in this photo. - www.doulos1914.blogspot.my

The story of the picture 'above' was that one day a few of us including myself was assigned to 'needle gun' the bilges in Hold No.1. In other words to clear the area of rust, prepare the area concerned with coats of primer. I was using the needle gun on a particular spot of thick rust and managed to remove a big chunk of it - there I noticed a dark, wet patch on the hull. Sea water! Mind you the Doulos was tied-up in port - that's the sea a few inches the other side of that steel plate! "Oops!!" I left that job for another. We had it 'patched up' during dry dock in Hong Kong not long after that incident. You can clearly see the rivets in the photo of the 'cutout'.

Hall of Names. 'Medina', just above the line and 'Franca C', behind the name 'Doulos'. - www.doulos1914.blogspot.my

The hull of the 'Medina' (MV Doulos 1991). Hull thickness was astounding, it 'passed 'many certifications all through the years to continue sailing. - www.doulos1914.blogspot.my

Today, in heavy steel fabrication, welding has almost completely replaced riveting as a means of making connections. Welds require less preparation of the metal, do not reduce the effective cross-section, and take a minimum of space. The miracle repeated itself year after year, one certification passed and then another - "Fit for service!" The dock certifiers found that the thickness of the hull was still the same thickness of when it left Newport News in 1914! Now that's a WOW!

No comments:

Post a Comment